We were pretty shocked when we unboxed this guitar to find that it had been badly damaged during shipping. It must have taken a very hard blow to the top. As you can see in the pictures we have a crack about 14″ long. There were a couple of other smaller cracks which will have to be dealt with as well, and the four braces that crossed the split had come detached from the top. We decided it would be a good opportunity for the apprentice to gain some experience on a big job.

Repairs

Get the most out of your 12-String Guitar

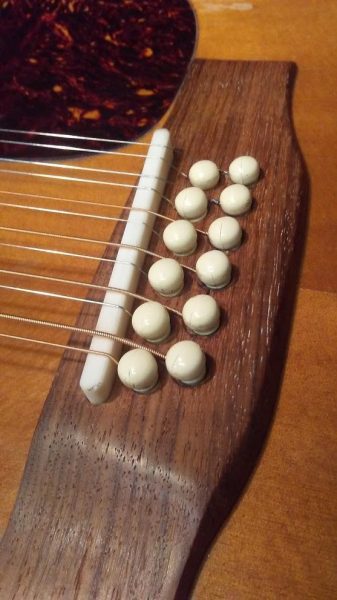

Here are some shots of a job we did on a customer’s 12-string guitar that really highlighted what a 12-string can really be with the special care and attention that these beasts require.

Cordoba F7 Flamenco Guitar Crack Repair

Both pictures are of the same guitar, two different cracks in the same top. Both have been glued up. The repair in the picture on the right was done before the guitar ever made it to our bench. The photo on the left shows the repair job that was done in our shop. Yes, there is a crack in that picture,

Familiar Face

This Gibson J-50 Deluxe was through the shop a few years ago for a major overhaul. A total of about $1200 of work went into it, including a new bridge, bone nut, bone saddle and a custom-fit set of bone bridge pins, New set of Kluson tuners, refinishing the top, a total refret and some fingerboard work, and splints and patches to fill some larger cracks. Oh yes, and this stylish

Turn of the Century B&J University Parlor Guitar

The top is solid spruce, neck is Spanish cedar with a hard “V”-shape, the back and sides appear to be birch. It recently had a refret, and a neck set done (not by us) as well as a new rosewood bridge made.

We were very lucky to come across this instrument at a decent price and found that just a bit more work could bring it to the next level.

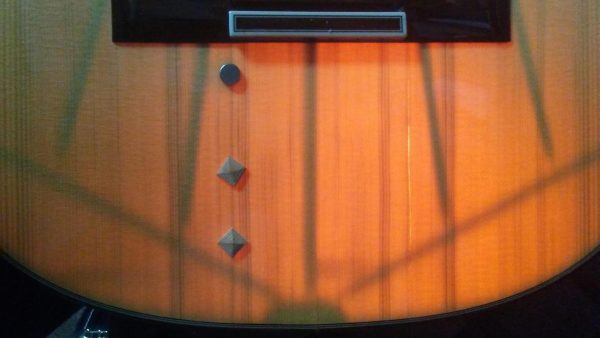

Soundport with magnetic door

Here’s a soundport I added to a clients Yamaha classical. With the door off the player receives a boost in volume and hears or experiences more of the guitars voice that is directed out the main sound hole towards an audience. The door can also be left on to keep the sound projection as it was which can be helpful when playing in a group and listening for everyones levels. Soundports are not a gimmick, they can definitely enhance the players experience, almost like a natural monitor. As with many advancements they were developed by hand builders and are now showing up in a few commercial instruments, along with arm bevels!

I Like to Wrap!

Violin Touch Up

baroque bow button repair

This bow accompanied a tenor viola da gamba that that came thru the shop. The button had long since cracked and disappeared.

Blues Repair

A guitar dropped at ‘just the right angle’, allowing it to impact on an edge will easily cause damage without much force, especially in cedar.

This is one of the Godin series of acoustics with some sort of poly based finish. More challenging to repair than a nitro type finish but doable with patience! Not 100% invisible but close.

Common Bow Repair

Frogs that are stubborn in movement when tensioning hair and have a gap between them and the stick are common and in many cases are due to a loose eyelet or, as in the case of this bow, an eyelet that was installed at an incorrect angle. Correct alignments and tolerances of all the components that join frog and stick together are a necessity if the frog is to move easily and to reduce wear on the parts. None of this is too surprising as tensioning the hair definitely produces some stress on these relatively delicate moving parts.

Correcting a loose or misaligned eyelet is usually straighforward with the wonderful eyelet alignment tool in the photo below. One can drill an oversize hole for an oversize shank eyelet at a perfect right angle to the underslide. Or one can drill out the entire damaged area and fill it with an ebony plug and redrill for a std eyelet depending on the situation.

This frog had an eyelet installed at quite an angle.

This frog had an eyelet installed at quite an angle.

Removed existing eyelet on left, drilled an oversive hole with tool pictured and installed thick shank eyelet.

Removed existing eyelet on left, drilled an oversive hole with tool pictured and installed thick shank eyelet.

Violin Crack Repair

This lovely violin had an old crack that was beginning to reopen and fill with grime, as seen to the left. Always more of a challenge when the crack ends blind in the middle of the top!

Below left, apologies for the blurry photo, one can see the caramelized sludge when the crack is flexed for cleaning. Below right is a photo after the crack has been cleaned, one has to be very careful to leave the wood intact while cleaning for a good glue joint.

The middle two photos below show the clamping during glue up and cleating processes. Cleating reinforces the crack and hopefully prevents another reopening.

The last photo at the bottom of the page shows the top reattached to the rest of the violin and varnish touch-up over the reglued crack, all done!

Adjusting wheels for Double Bass bridges

We take care of the details!

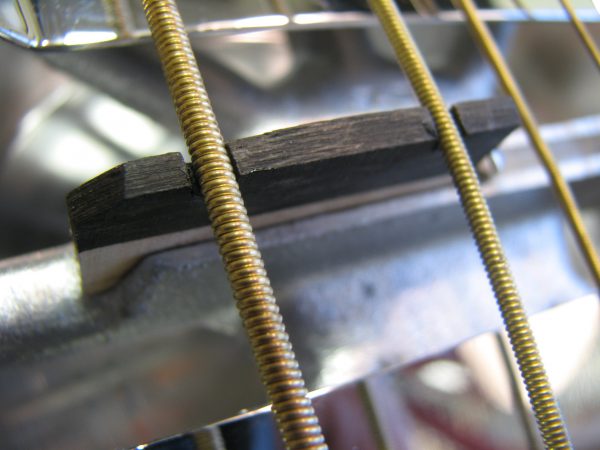

The fact is that many commercial guitars and violins have poor setup, not all, but many. Here are some photos of a maple/ebony saddle in the spider/bridge of a brand new resonator. The core of this guitar is fine, with decent quality for the money and a very good sounding american made cone from Paul Beard. The saddle however is not that well done and unfortunately it’s an important part of good tone production. These are the sorts of details I address on any instruments that I carry. Most of what I carry doesn’t have these issues but occasionally some of the instruments I sell do need some attention and rest assured that if they don’t get addressed before going on the floor for sale I try to make sure they get addressed before they get sold and even then you need only bring the instrument back to me after purchase and I will deal with these factory oversights free of charge.

Larrivee binding swap

As well crafted as Larrivee guitars are this client wasn’t enjoying the aesthetic of the ivoroid binding around the fingerboard and requested ebony replacements. As with many folks cost was a concern so I assessed the situation and decided the binding could be swapped out without a refret which reduces the cost greatly. Tricky job, fitting the replacement binding under the overhanging fret ends but the end result was perfectly acceptable and, as stated, a lot cheaper.

The humorous part of this repair story is I had collected ebony fingerboard offcuts years ago from the dumpster outside the Larrivee factory while living in Vancouver. For all I know the ebony I used of this job actually came from the same piece of fingerboard!

I should add, lest there be any confusion, this client had this done to two Larrivee guitars, thus the different instruments shown in process photos.

Capo removal and railroad spike install

GIBSON MASTERTONE REPAIR

In photo 1 the new railroad spikes can be seen and the screw holes from 2 previous capo systems on the side of the neck. After the screws for these intrusive systems were removed I drilled them slightly oversize to ensure roundness. Then proceeded to make a triple layer lamination of black and white celluloid with curly maple. The layup was too fragile to turn in my micro lathe so I quickly rounded the affair with a file and tapered each plug to get a snug fit in each hole.

In photo 2 the final touch up has been done. The curly maple stained, lacquer built up, leveled and buffed. This photo is up close but the end result is quite effective when viewed slightly farther away.